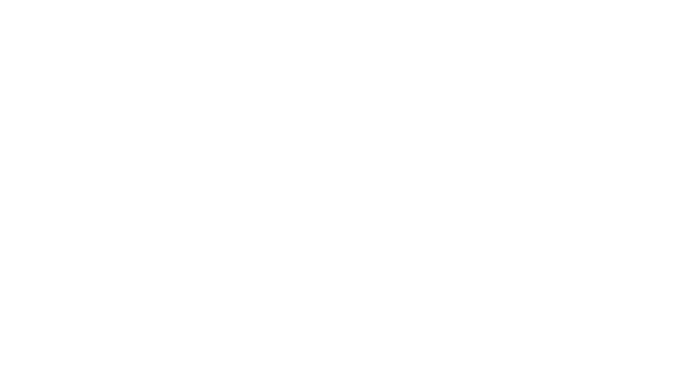

Two Common Options: In-House Printing & Outsourcing

In-House Label Printing

- The business invests in label printers, design/management software (such as BarTender), and supplies (paper, ribbons, etc.).

- Printing takes place directly at the factory or office, on demand, without relying on a third party.

Outsourcing Label Printing

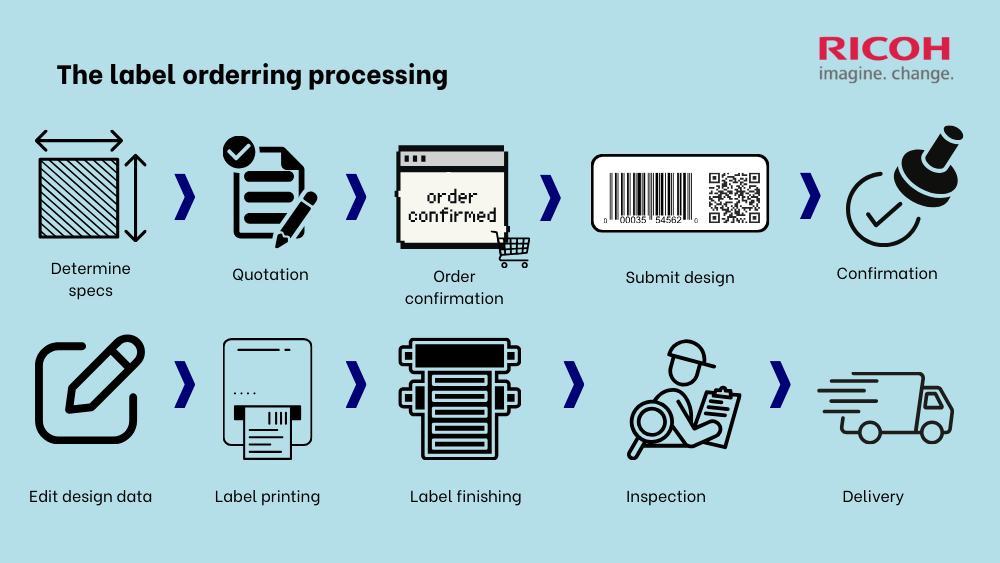

- The business orders from printing houses or label printing service providers.

- The process typically involves: sending requirements, getting a quote, approving a sample, waiting for printing, and receiving the goods. Turnaround time depends on the printer’s production schedule, usually ranging from 4 to 7 days

| Internal Printing | Outsourcing |

| Design & print on-site | Submit request, wait for quotation |

| Print on demand | Approve sample, wait for printing schedule |

| Control quantity & timing | Receive goods & store in inventory |

Pros & Cons of Each Option

To compare the advantages and disadvantages of these two options, Ricoh will analyze them based on the five criteria below:

Speed & Control

- In-house printing: Print instantly when needed, full control over delivery time. Ideal for urgent or frequently changing orders.

- Outsourcing: Dependent on the printing supplier’s production and delivery schedule; delays can occur when changing label designs or quantities.

Design Flexibility & Variable Data

- In-house printing: Easily modify layouts and add variable data (barcodes, QR codes, batch info) right before printing.

- Outsourcing: Any change requires sending a new file for approval, which takes time and may incur extra fees.

Production Cost per Label

- In-house printing: Lower unit cost for frequent small to medium print runs.

- Outsourcing: Cost-effective for very large batches (economies of scale) but less efficient for small or on-demand jobs.

Total Cost of Ownership (TCO)

- In-house printing: Requires upfront investment in printers, software, and supplies; includes maintenance costs. However, it can save money in the long run if printing needs are consistent.

- Outsourcing: No initial investment, but cumulative operating costs may be higher over time.

Quality & Finishing

- In-house printing: Quality depends on printer, ribbon, and media; when chosen correctly, it meets industrial standards.

- Outsourcing: Large-scale industrial printing with consistent quality and advanced finishing options (foil stamping, varnish, die-cutting).

Summary Table:

| Criteria | In-house Printing | Outsourcing |

| Speed & Control | + Instant printing – Requires maintenance & spare supplies | + No equipment investment – Longer lead time, rush fees |

| Design & Data Flexibility | + Variable data, quick edits – Needs template management | + Best for fixed designs – Time-consuming to update |

| Unit Production Cost | + Cost-effective for small runs – Equipment depreciation | + Low cost for huge batches – High cost for small runs |

| TCO (12–24 months) | + Long-term savings if frequent changes – High CapEx | + No CapEx – High OpEx if frequent changes |

| Quality & Finishing | + Excellent for barcodes/durability – Limited premium effects | + Superior for full color/special finishes – Slower for changes |

Note: (+) for advantages and (-) for disadvantages

Which option should you choose?

When to outsource printing

- Printing needs change very little, with a stable design template.

- Each print run is in very large quantities (e.g., over 50,000 labels).

- Requires complex finishing techniques that are difficult to execute in-house.

When to invest in in-house printing

- The business produces many small batches or custom orders.

- Labels frequently need updated product information, barcodes, production dates, or QR codes.

- Want to reduce waiting time and have full control over timelines.

- Want to optimize long-term costs when printing demand remains high.

New trend: Businesses are shifting toward proactive in-house printing

Recent market surveys show a strong movement toward on-site printing:

- According to Smithers Pira 2024, the demand for on-site label printing in the Asia-Pacific region is growing by 8.3% per year, driven by the need for speed and higher personalization.

- The 2023 Finat Radar report shows that over 40% of food manufacturing companies in Europe have partially or fully switched to in-house printing.

This trend is not limited to large corporations. Small and medium-sized enterprises are also leveraging in-house label printing technology to reduce long-term costs, shorten lead times, and improve market responsiveness.

Ricoh’s complete in-house label printing solution

Ricoh Vietnam offers a comprehensive, fully developed, easy-to-deploy, and optimized solution for food manufacturing businesses:

- Zebra printers – Durable, high-performance, and suitable for all production environments.

- Ricoh consumables – High print quality, durable materials in various environments, and compliant with international safety standards.

- BarTender software – Flexible label creation, management, and printing with advanced features.

- Dedicated support services – Label design consultation, on-site demos, and free material testing.

With Ricoh, you get:

- 100% control – Print anytime without relying on third parties.

- Fast response to changes – Easily adjust and integrate as needed.

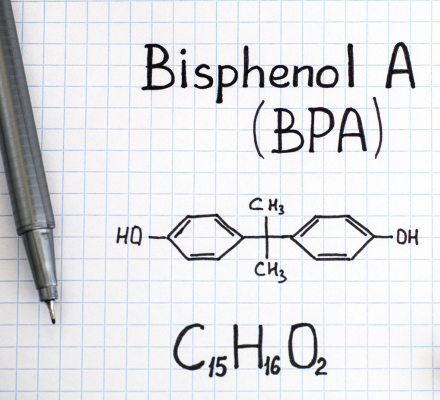

- Export-compliant labels – Meeting standards such as UL, RoHS, REACH, MSDS, BPA Free, MOAH/MOSH, and more.

- Long-term cost optimization – Reduce intermediaries and avoid dependence on minimum order quantities (MOQs).

Conclusion

There’s no single “right” answer for every business when choosing between in-house printing and outsourcing. However:

- If you want speed, flexibility, and full control, seriously consider investing in in-house printing.

- If your needs are stable and your MOQs are very large, outsourcing is still a good solution.

Tip: Analyze based on total cost of ownership (TCO) and the value of time. In a fast-changing market, in-house printing is becoming a significant competitive advantage.

Contact Ricoh Vietnam today to get a comprehensive advices

Let’s connect

Get in touch with one of our consultants and find out how we can help you to implement a barcode system

Recommended resources for you

.png)

Things You Should Know About Warehouse Management in 2024

Discover the top trend of warehouse management in 2024

Direct Thermal or Thermal Transfer: Which One To Choose?

This article will provide step-by-step guidance to help you navigate the world of thermal printing technology.