Top 5 UL969 Mistakes Vietnamese Factories Make

1. Using Materials/Components Not UL Recognized

This is the most common mistake. Many factories use materials or assemblies not listed as UL Recognized, making it impossible to prove product safety. You can refer to the UL Compliance Guidelines for appropriate certification categories.

- Non-compliant components: e.g., using an LED power supply that meets general standards but not the specific safety requirements mandated by UL.

- Safety risks: faulty lithium-ion batteries, electromagnetic interference (EMI), overheating, or substandard wiring can cause fire or electric shock.

- Design complexity: for complex products such as rigid-flex circuits, proving compliance becomes more difficult and costly.

2. Incomplete Documentation and Records

One of the main reasons companies fail UL inspections is inaccurate or incomplete documentation.

- Missing documents: insufficient information about materials and testing processes.

- Certification confusion: many companies confuse UL Listed (for finished products) with UL Recognized (for components).

3. Unauthorized Design or Production Changes

Some factories change the Bill of Materials (BOM) or relocate production sites without notifying UL. This directly affects product quality and compliance. All changes must be approved and verified by UL field engineers.

4. Lack of Essential Safety Features

Common safety violations found during inspections include missing machine guards, improper wiring (e.g., no strain relief), non-functional Emergency Off (EMO) switches, or missing safety warning labels.

All safety mechanisms should be implemented through verifiable electromechanical means. These issues are easily detected during inspections and can result in loss of UL certification.

5. Labels Failing Durability Tests

Labels and markings must be durable enough to withstand the intended environment and meet specific standards such as UL969. If labels fail durability tests, companies face costs for re-labeling, re-testing, and re-auditing.

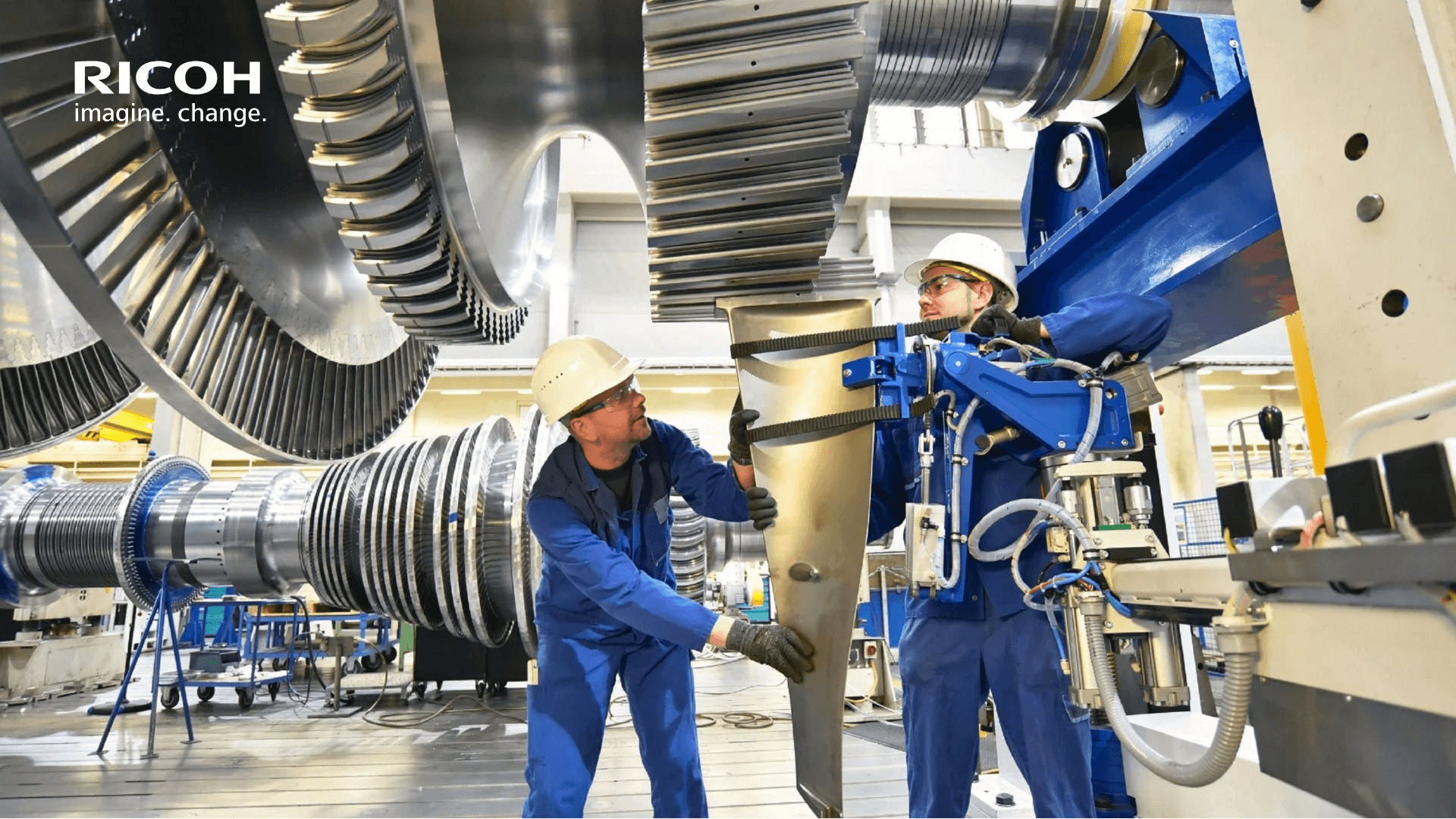

Supply Chain and Market Access Barriers

Achieving UL certification is difficult, and maintaining quarterly UL compliance is even more challenging. Beyond technical factors, the supply chain plays a major role in sustaining UL certification:

- Retailer requirements: while not mandated by law, most major retailers refuse to sell products without UL certification.

- Import issues: customs authorities in the U.S., Europe, and Canada may require UL documentation; missing documents cause delays.

- Legal liability: selling non-compliant products can expose companies to lawsuits.

- Cost and time: the UL certification process is expensive and time-consuming, creating significant pressure on manufacturers.

Conclusion

In practice, UL certification is not only a technical requirement but also a business strategy that helps Vietnamese enterprises build trust, minimize legal risks, and expand into international markets.

Avoiding the five common UL969 mistakes will enable factories to enhance credibility, ensure product safety, and strengthen global competitiveness.

To support businesses in better understanding UL standards in general, and UL969 in particular, as well as reducing the pressure from regular UL audits, we are pleased to introduce the online seminar:

“From Pitfalls to Smart Compliance: How Vietnamese Factories Win UL Audits”

Within the framework of this webinar, you will:

- Learn how to leverage the UL Certified database to select the right labels.

- Gain access to processes for building and maintaining traceability records, ensuring full compliance with UL inspection requirements.

- Receive practical insights from experts on turning UL certification into a competitive advantage.

By joining the webinar, you will have the opportunity to connect directly with specialists and gain the confidence to successfully pass UL audits 👉

Catch Up With UL969 Now

Webinar - From Pitfalls to Smart Compliance: How Vietnamese Factories Win UL Audits

Recommended resources for you

How to Build Collaborative Work Environments for Hybrid Workforces

Unlock the full potential of your workforce. Learn how collaborative solutions can enhance communication, boost productivity, and foster innovation across dispersed teams.

How to Secure Your Digital Workplace from Cyberattacks

Learn how to protect your digital workplace from cyberattacks, safeguarding your data, reputation, and business.

How to Create a Hybrid Workplace That Works

Uncover strategies to build an inclusive hybrid workplace that boosts productivity and engagement.