Classification by Composition

This is the most common method of classification, dividing ribbons into three main types: Wax, Wax/Resin, and Resin.

Wax – Cost-effective, for paper labels with low durability requirements

- Composition: Mainly wax with some carbon black

- Advantages: Low cost, high print density, compatible with most printers

- Best suited for: Product labels, domestic shipping, consumer goods that don’t require long-term storage

- Limitations: Poor resistance to abrasion, chemicals, or high heat

Wax/Resin – A balance between cost and durability

- Composition: A mix of wax and resin, providing better adhesion and physical durability

- Advantages: Sharper print quality than wax, good durability, still cost-effective

- Best suited for: Logistics labels, warehouse tags, export packaging

- Label materials: Works with both paper and some synthetic films

Note: Some businesses refer to this type as Semi-Resin

RibbonResin – High to Maximum durability for harsh environments

- Composition: Primarily resin and carbon pigment

- Advantages: High resistance to abrasion, chemicals, and extreme temperatures

- Best suited for: Chemical product labels, medical device labeling, outdoor usage, or industries requiring strict compliance (RoHS, UL, etc.)

- Limitations: Higher cost, requires compatible printer and high-quality synthetic labels

Comparison Table:

| Criteria | Wax | Wax Resin | Resin |

| Print density | 5/5 | 4/5 | 3/5 |

| Durability | 2/5 | 4/5 | 5/5 |

| Chemical Resistance | 0/5 | 2/5 | 5/5 |

| Material Compatibility | Paper | Paper & Film | Film |

| Cost | Low | Medium | High |

Note: This comparison is based on data compiled by Ricoh from multiple sources.

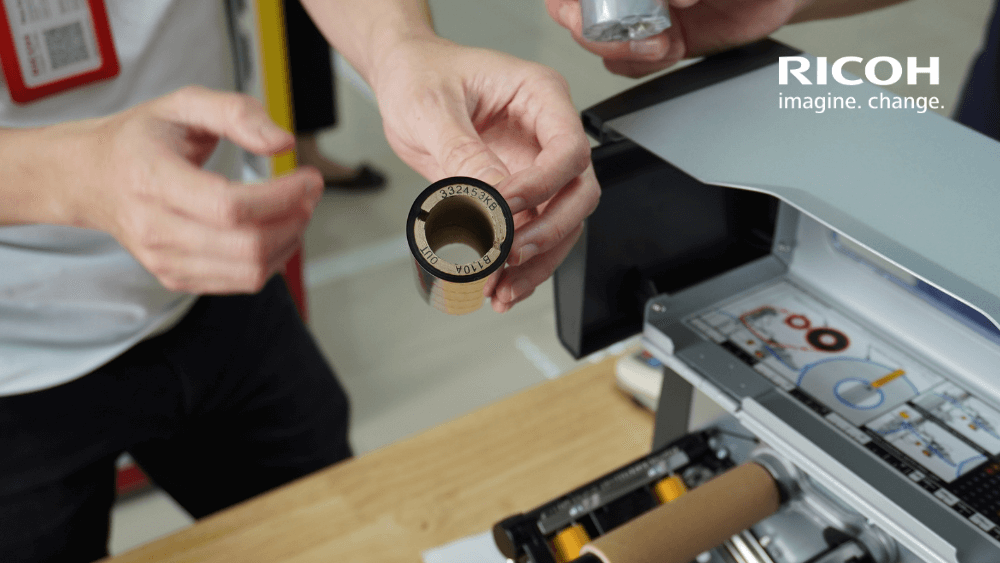

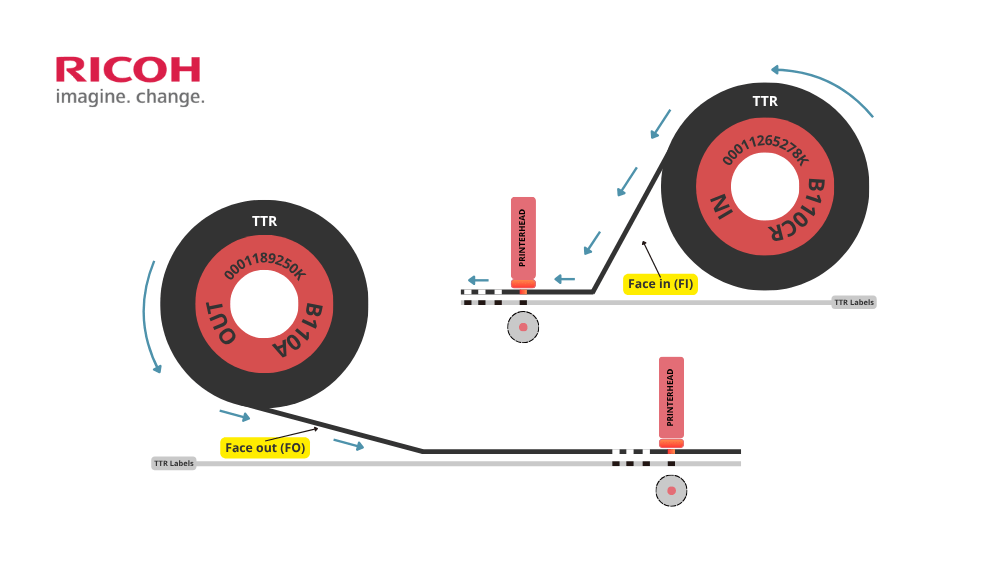

Classification by Ink Side

Depending on the printer model, the ink side of the ribbon differs and is categorized as:

Ink Side Out

- Most commonly used in the market

- Compatible with most desktop and industrial label printers

- Identification: The black ink layer faces outward; you can scratch it with a fingernail to see ink come off

Ink Side In

- Less common, used for specific printer models

- Requires correct installation to avoid printing errors or printhead damage

- Typically used in specialized packaging linesChoosing ink-in or ink-out doesn’t affect print quality, but it directly impacts ribbon installation. Always check your printer’s ribbon orientation before purchasing.

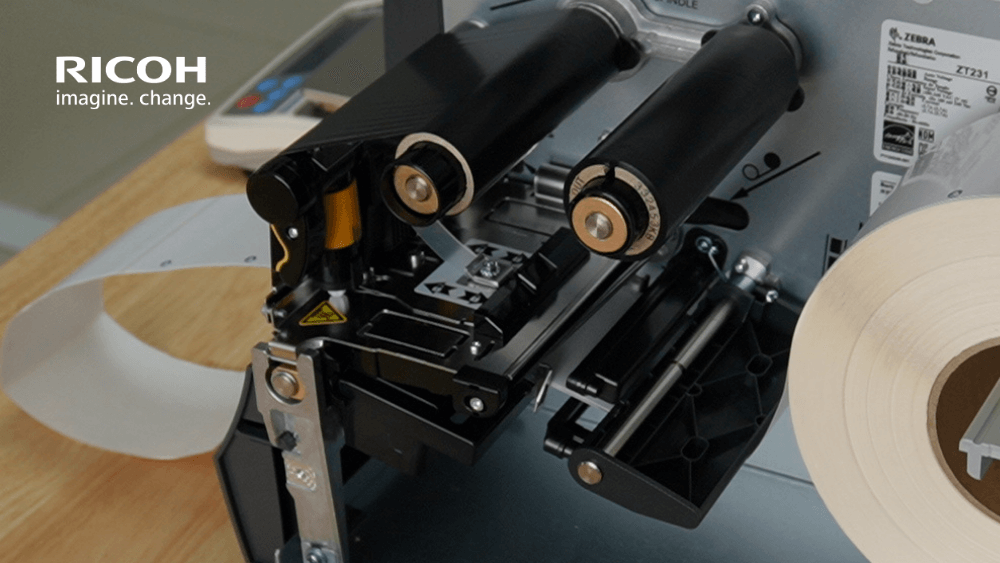

Classification by Printhead Compatibility

Thermal transfer printers generally use two types of printheads: Flat-head and Near-edge. Each ribbon type is optimized for a specific printhead type.

Flat-head Compatible

- Most common; supports a wide variety of ribbons

- Produces sharper images at moderate print speeds

- Compatible with most desktop printers (e.g., Zebra, TSC, Sato)

- Ricoh recommendations: B110CU, B110CR, B125CS

Near-edge Compatible

- Designed for high-speed printing, especially on automated packaging lines

- Transfers heat faster and requires ribbons with higher sensitivity

- Common in industries like food packaging, pharmaceuticals, and industrial manufacturing

- Ricoh recommendation: B120E

Some ribbon types from Ricoh are optimized for flexible use across both flat-head and near-edge printers. Examples include B120HS, B120EC, and industry-specific types like D110A, D110C for garment and textile printing.

Classification by Product Line

At professional manufacturers like Ricoh, ribbons are grouped by performance and durability levels to help customers select more easily:

High-Performance Series

- Versatile printing with exceptional efficiency

- Compatible with a wide range of materials

- Ricoh recommendation: B125CS, B110M, B110TI

High-Speed Series

- Optimized for high-speed and large-volume printing

- Ideal for production lines and bulk printing

- Ricoh recommendation: B120HS

High Durable Series

- Good resistance against common solvents and chemicals

- Produces sharp images and supports small barcode printing

- Ricoh recommendation: D110C, D110A, B120EC

Ultra-Durable Series

- Maximum durability for extreme environments

- Resistant to strong chemicals, high heat, and long-term outdoor exposure

- Ricoh recommendation: B110CU, B110CR

Read more, how Ricoh Resin B110CU (with RFR) and B110CR help your labels durable in harsh environments

Conclusion

There is no one-size-fits-all ribbon. The “right” thermal transfer ribbon depends on your label type, usage environment, print durability needs, printer specifications, performance expectations, and budget.Understanding how thermal transfer ribbons are classified is the first step toward selecting the right ribbon for your operations.

Contact Ricoh Vietnam today for free consultation with experienced Auto-ID solution experts.You can also request free ribbon samples to test print performance directly at your site before making a large-scale investment.

Let’s connect

Get in touch with one of our consultants and find out how we can help you to implement a barcode system

Recommended resources for you

.png)

Things You Should Know About Warehouse Management in 2024

Discover the top trend of warehouse management in 2024

Direct Thermal or Thermal Transfer: Which One To Choose?

This article will provide step-by-step guidance to help you navigate the world of thermal printing technology.

What’s for barcode labels – Thermal or Laser Printing?

Most businesses typically have laser printers for their printing needs within the company. Therefore, most people consider using a laser printer when considering label printing. However, thermal printers specialized for label printing have distinct advantages in terms of printing speed and minimizing issues such as paper jams or adhesive sticking.